Candle Filters for High Performance Solid Liquid Separation

Why Are Candle Filters Important in Today’s Industrial Operations?

Modern processing environments demand filtration systems that deliver operational robustness, scalable performance and long-term reliability. As organizations pursue efficiency, sustainability and risk-controlled production, candle filtration has become a strategic technology choice. As a Swiss engineering company, DrM builds its FUNDABAC® and CONTIBAC® systems on deep application expertise and rigorous design standards, providing predictable filtration results across varied industrial duties. DrM’s patented heel volume filtration further enhances process reliability by securing complete cake recovery even at minimal liquid levels.

What Makes Candle Filtration a Reliable Method for Complex Slurries?

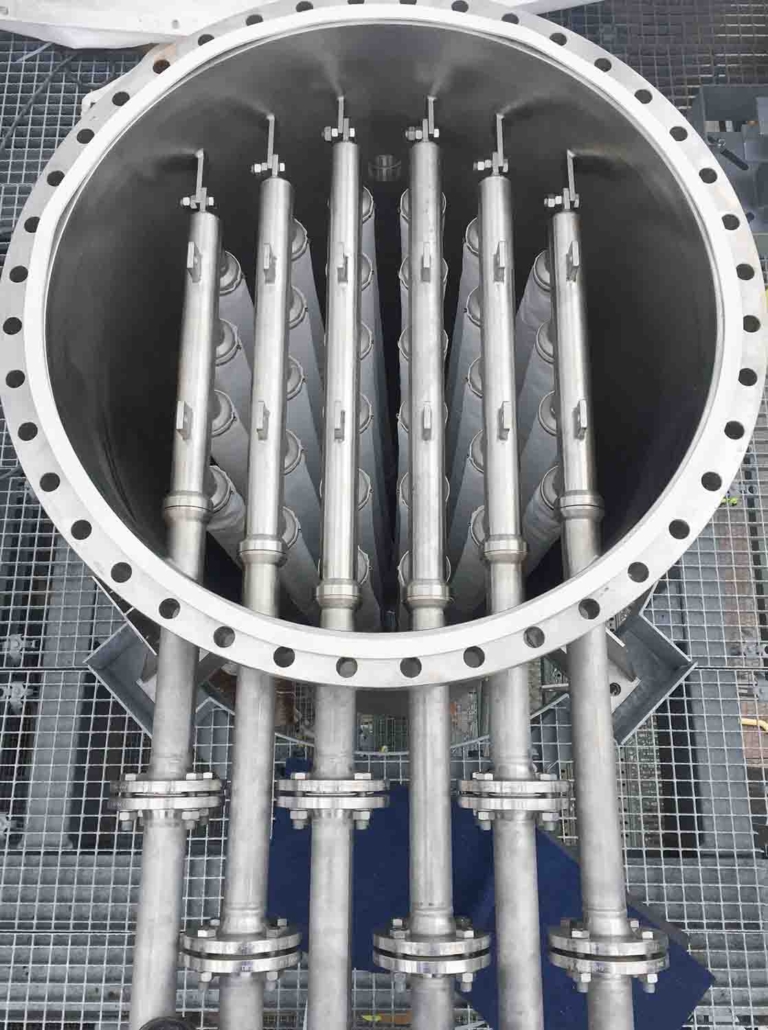

Candle filters function through a pressure driven process where solids are retained on filter media wrapped around vertical candle elements. This architecture supports the processing of fine particles, compressible solids and heterogeneous slurries. Published studies illustrate the capability of candle type systems to generate uniform cakes, maintain stable differential pressures, and secure high clarity filtrate. The design enhances these fundamentals with engineered elements that support predictable cake build up across changing feed conditions.

Why Is Enclosed Operation Essential for Modern Processing?

Enclosed filtration systems reduce exposure risks, eliminate open handling, protect the environment and provide controlled process conditions. This becomes critical when dealing with sensitive intermediates, solvent based formulations, hazardous materials, or streams where cross contamination must be prevented.

DrM candle filters are engineered as sealed pressure vessels that support automated sequences, clean operating conditions and compliance with modern hygiene and safety expectations.

How Do Candle Filters Optimize Cake Formation and Discharge?

Controlled cake formation is central to filtration performance. FUNDABAC® and CONTIBAC® candle filters use vertical elements with carefully engineered drainage channels, high precision media supports, and pressure profiles that promote homogeneous cake build up. This improves cake stability, enhances washing efficiency, and supports consistent drying.

How is a Reliable Dry Cake Discharge Made Possible?

A combination of mechanical design and process functions have built the foundation of the DrM candle filter to accomplish a reliable discharge of a gas-dried cake with powdery consistency. The central tube allows complete drainage of residual liquids while the clover-shaped element assures effective discharge. Correct pipe design, valve placement and instrument location as well as controlled process conditions such as pressure differentials during the draining and drying process make sure the cake is washed, dried and discharged effectively.

What is the Process for Dry Cake Discharge?

Once the cake is dried to the required level, the systems use a gas backwash discharge mechanism. Pressurized gas is pulsed through the filter elements to release and discharge the cake in a controlled manner. This approach minimizes mechanical wear, eliminates manual handling, and ensures consistent cycle performance. The enclosed design keeps the discharge process contained, clean, and aligned with modern safety and operational requirements. This discharge principle, combined with heel volume removal, maximizes yield and reduces product losses.

How Are Candle Filters Customized for Each Customer Application?

Every slurry behaves differently. For this reason, DrM designs each system through a structured engineering and testing approach that includes:

- Laboratory and pilot scale filtration tests to determine cake resistance, compressibility, and washing behavior

- Evaluation of flow rates, solids loading, and operating pressure ranges

- Media selection based on particle size distribution, chemical compatibility, and required filtrate clarity

- Sizing simulations to optimize element count, vessel diameter, and hydraulic configuration

- Assessment of utilities, automation requirements, and available space

- Process integration support to ensure seamless alignment with upstream and downstream operations

This engineering approach ensures each installation meets specific performance targets rather than relying on generic sizing. The result is a filter tailored to real process conditions and long-term reliability.

What Materials of Construction Support Operational Flexibility?

Material selection plays a critical role in plant reliability and lifecycle performance. DrM applies a structured materials approach to ensure each candle filter matches the customer’s chemical and thermal environment.

Typical options include:

- 316L stainless steel for standard applications with broad chemical compatibility

- Higher alloys such as 904L, Duplex 2205, Hastelloy or titanium for corrosive or high purity requirements.

- Special linings including rubber lining, glass lining and fluoropolymer sheet liners like PTFE, PFA or ETFE for highly aggressive media.

- Internal components made from various stainless steels, Titanium, Polypropylene, PVDF or PPS.

- Wide selection of filter media (including ss316 mesh for up to 400ºC) to adopt to solids and process conditions.

- Application specific combinations selected to ensure long service life, stable performance and cost-efficient operation.

This portfolio allows DrM to engineer systems that remain stable even under extreme chemical or thermal loads.

How Can Candle Filters Scale Across Different Throughput and Purity Requirements?

Candle filtration is inherently modular. Systems can be configured for small pilot units, mid-scale production lines, or large industrial installations. DrM supports scaling through vessel sizing, candle element count and application specific process configuration to match required throughput and clarity targets.

Automation levels can also be tailored, ranging from fully automated CIP capable systems to simpler, semi-automated configurations. Vertical vessel design optimizes footprint, while modular skids support efficient installation in both greenfield and brownfield projects. This flexibility ensures operational continuity across different production phases.

How Do Candle Filters Support Sustainability and Operational Efficiency?

Candle filtration contributes directly to sustainability and long-term operational efficiency by enabling low energy demand, reduced consumables usage and extended filter element service life. The closed configuration minimizes solvent losses, lowers emissions and reduces waste volumes, while automated sequences for cake discharge and cleaning improve worker safety and support consistent operations. Instrumentation can be integrated to monitor pressures, flows and cycle steps, supporting stable cycle performance and reliable operation.

FUNDABAC® and CONTIBAC® systems provide high clarity filtrate, stable cake formation and dependable process control, supporting efficient operation in diverse applications. Combined with heel volume filtration and proven automation concepts, DrM candle filters offer a reliable foundation for future oriented process design.