High solids capture efficiency.

Fully enclosed design and automatic operation.

Customizable filtration area.

Very low operating costs.

Bottom outlet for consistent slurry drawn off.

High solids capture efficiency.

Fully enclosed design and automatic operation.

Customizable filtration area.

Very low operating costs.

Bottom outlet for consistent slurry drawn off.

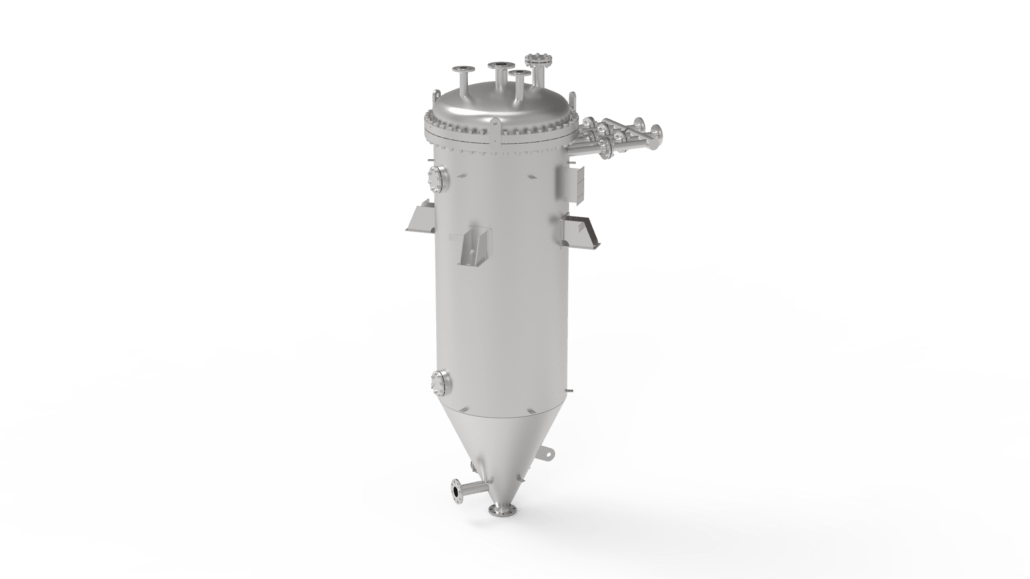

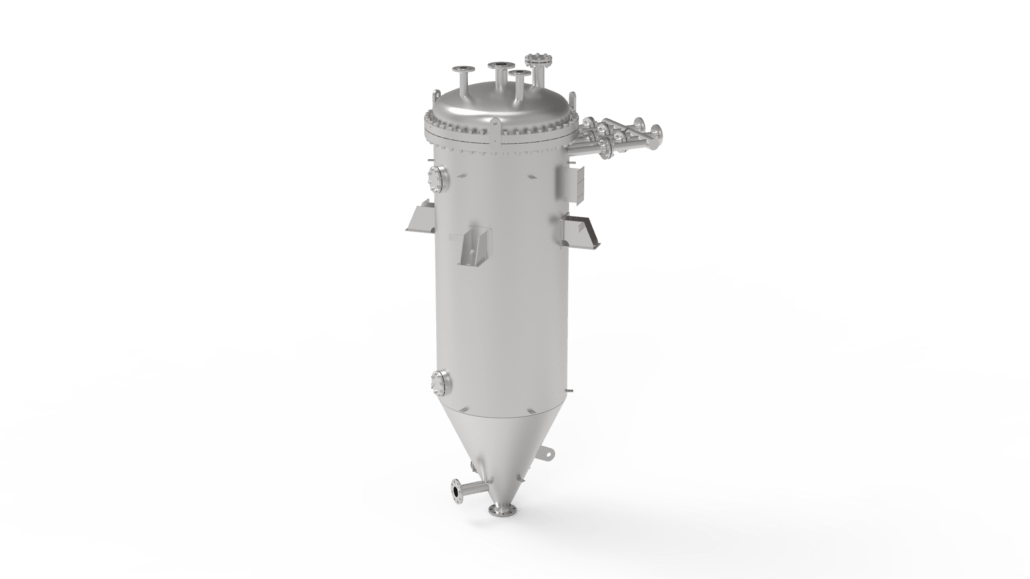

The CONTIBAC® is a slightly modified FUNDABAC® candle filter used as a continuous filter thickener, producing concentrated slurries. Clear filtrate at a high flow-rate is achieved. As a self cleaning filter, a CONTIBAC® features back-washable filter elements that are flushed back with compressed gas or clear filtrate so that solids get freed into the liquid and the resulting thickened slurry is drawn off intermittently or continuously from the bottom outlet of the filter. This solid-liquid separation process mainly applies when a continuous or semi-continuous flow is required and inlet suspended solids are minimal. For inquiries or further information, please have a look at our Downloads page.

Decolorization of mother liquor in adipic acid production.

Mercury removal from crude oil to prevent upsets in downstream processes, such as contamination of precious metal hydrogenation catalyst used in catalytic cracking.

Removal of carbon and FeS scale in amine treatment.

Suspension preparation of fibres and solvents.

Removal of mineral gangue solids from rare earth element rich liquor.

Sulfur removal in redox sulfur recovery processes.