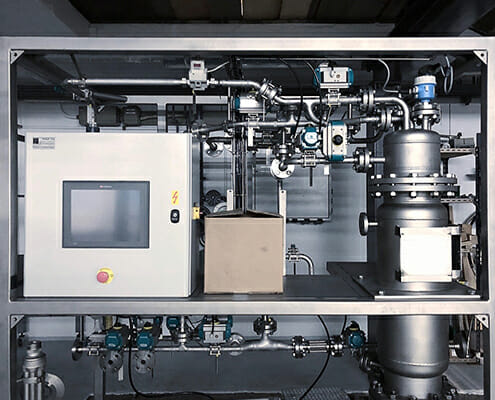

DrM Filter Testing Pilot Plants & Scale Up

In many chemical processes, the filtration step is considered a bottleneck. Therefore a properly designed filter that factors in its sizing is critical for successful plant operation.

In addition to DrM’s extensive filtration experience and know-how in hundreds of different processes which DrM has acquired as a result of its 3000 filter references, DrM is capable of supplying a wide array of pilot filters ranging from lab scale (0.012 m2 filtration area) to industrial production scale (50.7m2 filtration area).

Many conclusions can be drawn as a result of observing the following 8 pilot testing aspects:

1. An accurate flux rate per m2, essential in order to properly size an industrial filter, can be determined

2. The best performing filter cloth can be selected as a result of observing filtrate quality

3. The determination of filter cake thickness

and dehydration potential, as well as filter cake discharge behavior (the latter, in the case of the FUNDABAC® filter)

4. The performance of filter cake washing, if required for the process

5. The determination of optimal filter cake formation

6. Solids concentration or Total Suspended Solids (TSS), in the case of CONTIBAC® slurry discharge

7. Determination of an optimal cloth cleaning procedure to ensure original flow rate repeatability, batch after batch to ensure a much longer cloth life time

8. Cake discharge procedure as a result of cake discharge observation

DrM has recently developed a new test software in which the most important parameters for filtration unit design are highlighted. The parameters include:

– Required flow rate to correctly size a filter

– Cake thickness and dryness to obtain an accurate estimate of waste associated costs or alternatively the design of post treatment driers

– Optimum total cycle time considering both filtration and down times (filter filling, draining, drying, washing and cake discharge)

Once key parameters are known, industrial filter sizing for optimal operation can be determined accordingly.